Overview

The five core libraries shown in the table enable the development and implementation of energy management and operational strategies as well as component dimensioning and scenario-based energy studies.

Software library modules

| Module | Description | Main features |

|---|---|---|

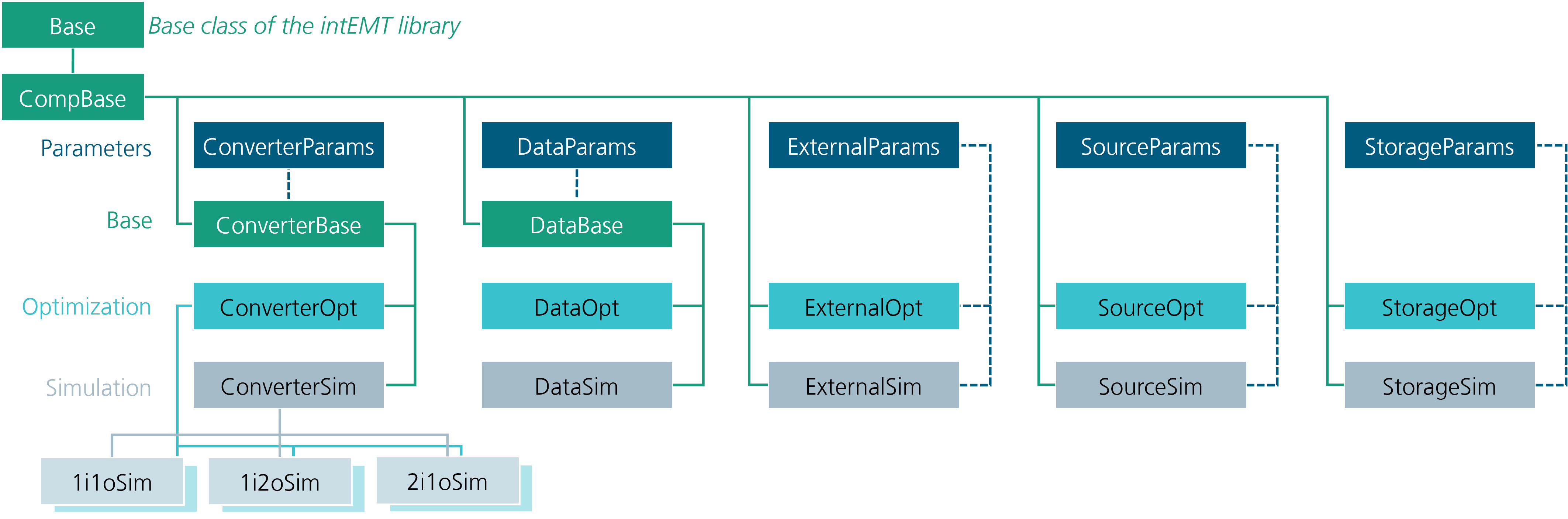

| Component models | Generalized modelling approach for the energy technology components covering numerous use cases |

|

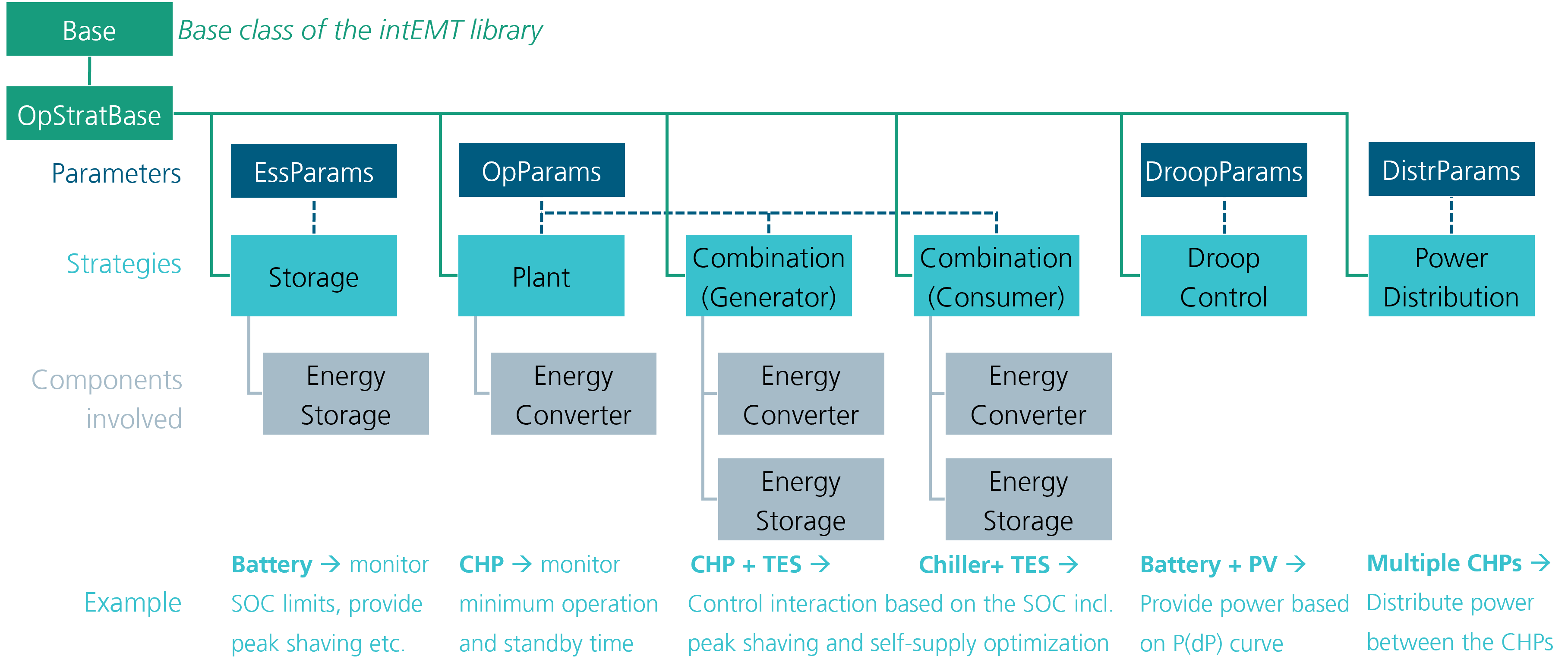

| Operational strategies | Operational strategies for plants with or without storages, can also be used stand-alone |

|

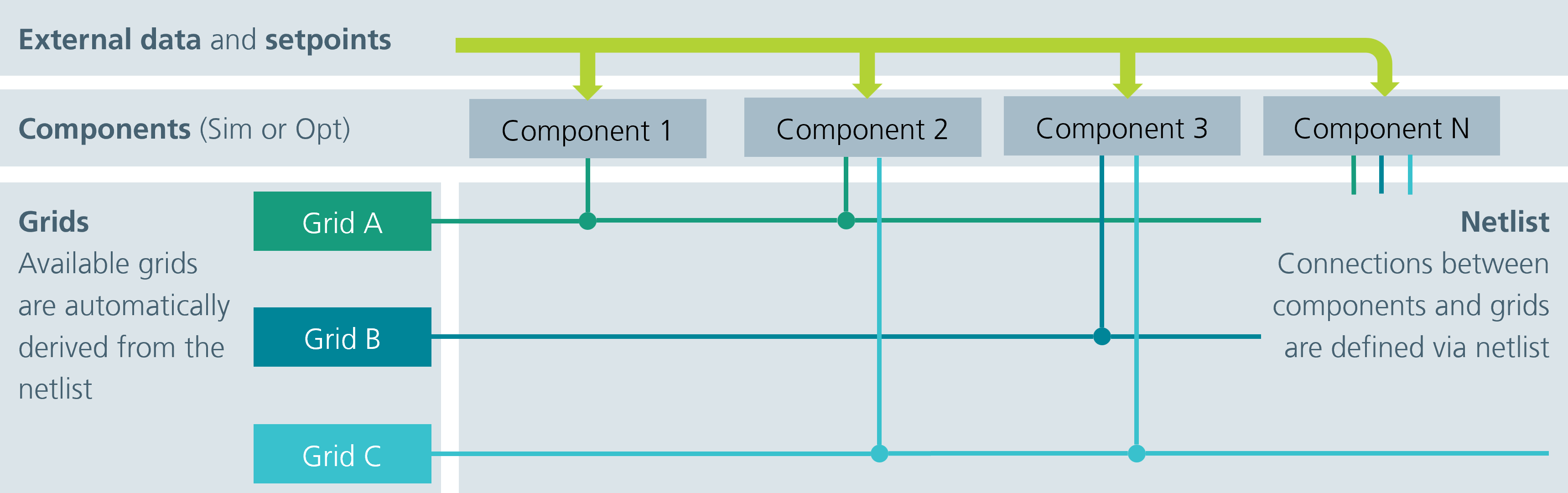

| Systems | Energy systems where components are connected with grids |

|

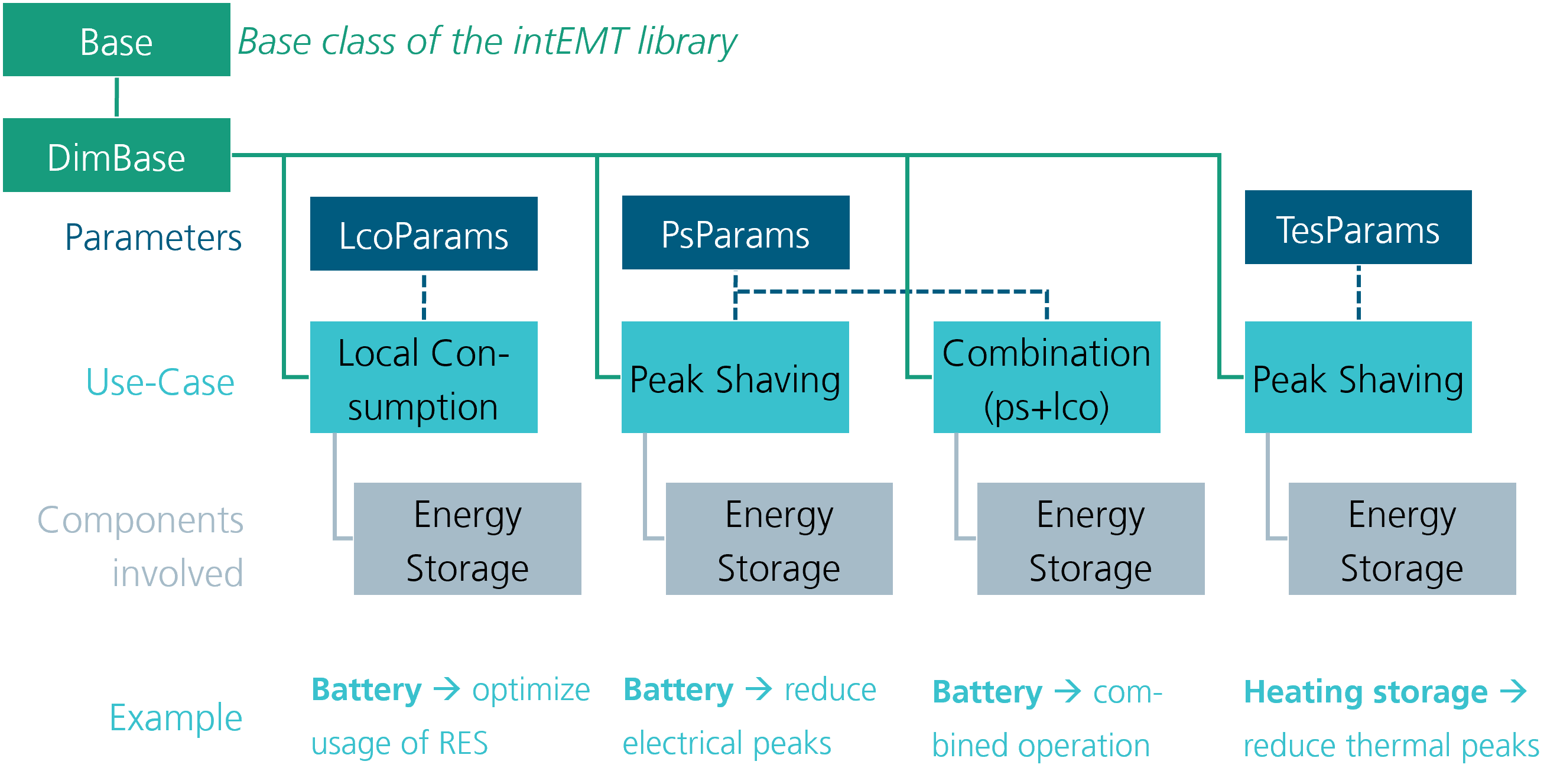

| Dimensioning | Sizing of energy storages and plants for various applications |

|

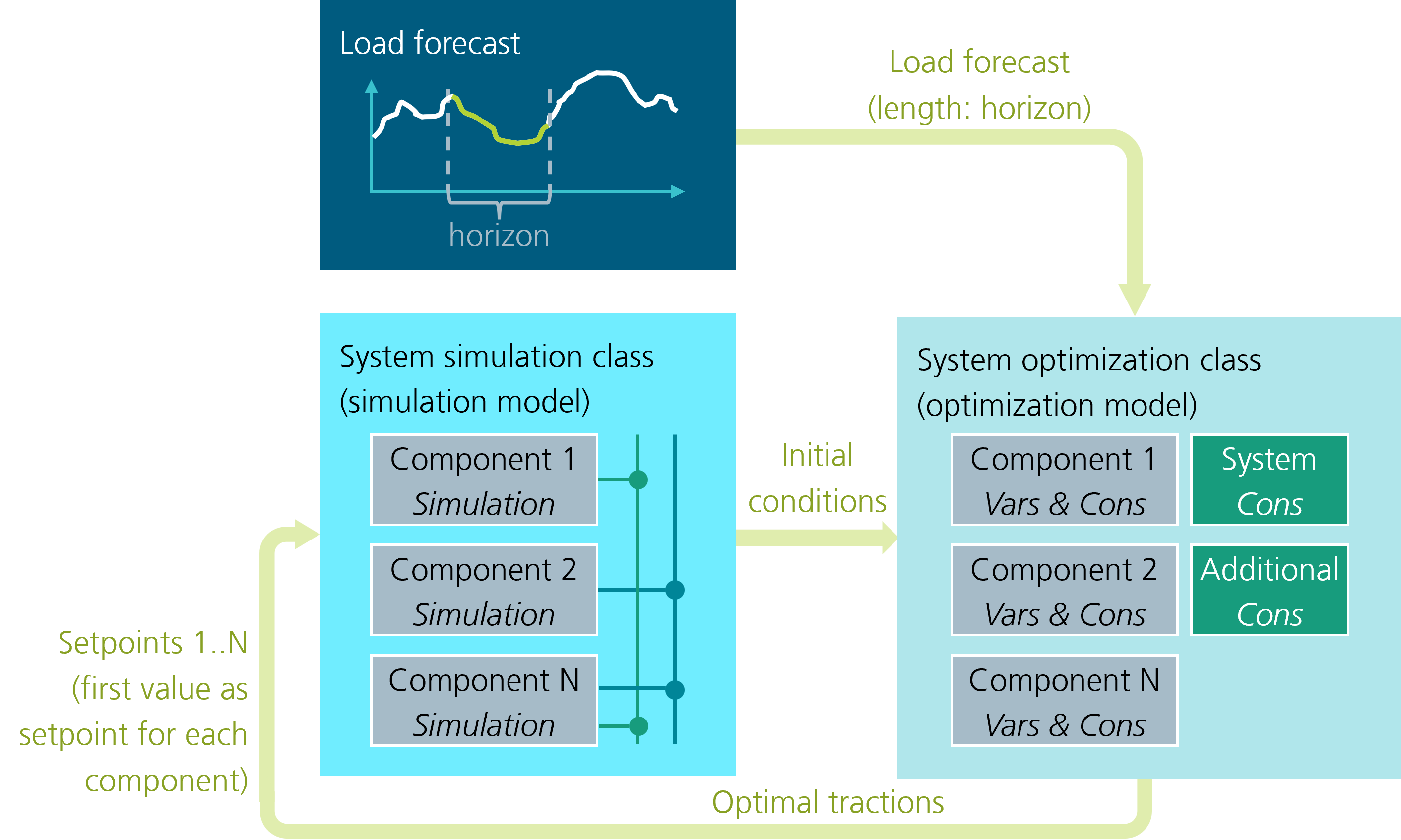

| Energy Management | Economic Model Predictive Control (eMPC) based energy management |

|